1. The required investment of the equipment is 1/6 of the imported products other countries

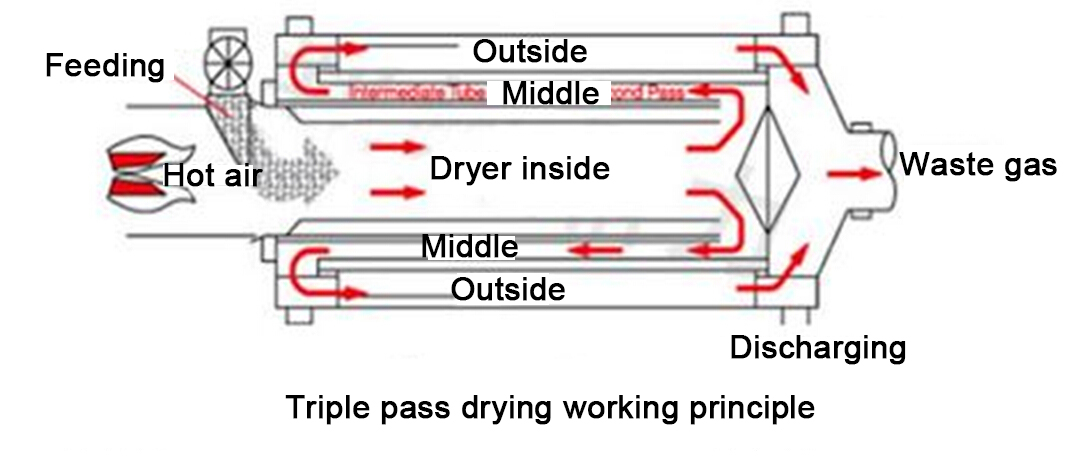

2. The self-heating thermal efficiency of the dryer body is as high as 70% (the thermal efficiency of the traditional single drum dryer is only 35%), and the heat efficiency is increased by more than 50%

3. Compared with the single drum dryer, it will reduce the land occupation by about 50%; the civil construction investment will be reduced by about 50% the electricity consumption will be reduced by 60%

4. Combination of Multi-directional lifting, which can regulate of drying time effectively and get good drying effect

5. According to user requirements, the dryer can easily regulate the final moisture as customer desired

6. Use frequency control speed to control material flow

www.woodpelletmill.cn

www.woodpelletmill.cn