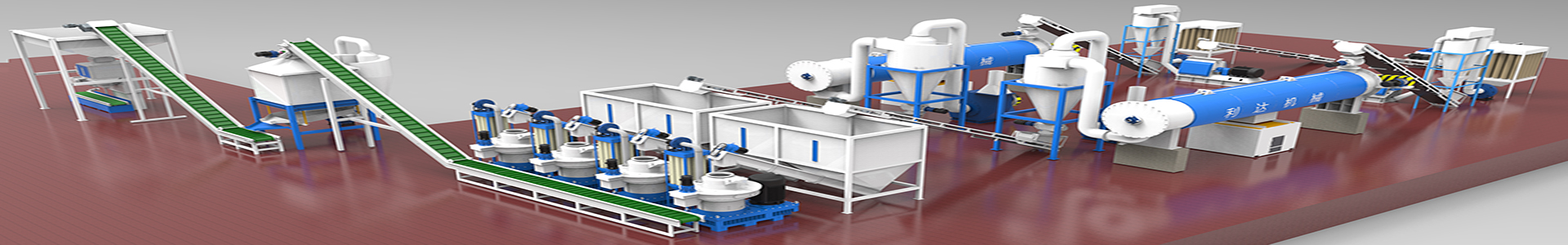

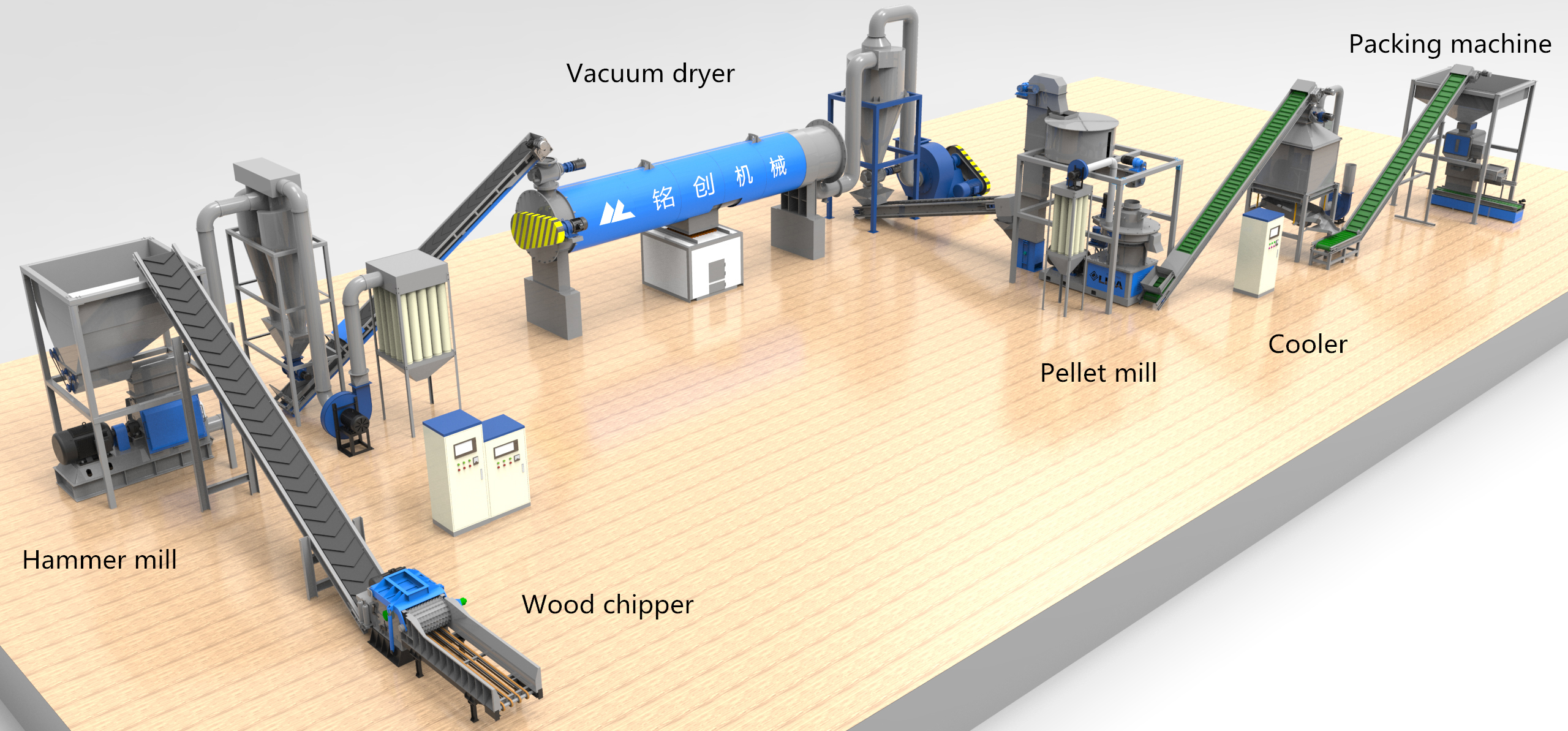

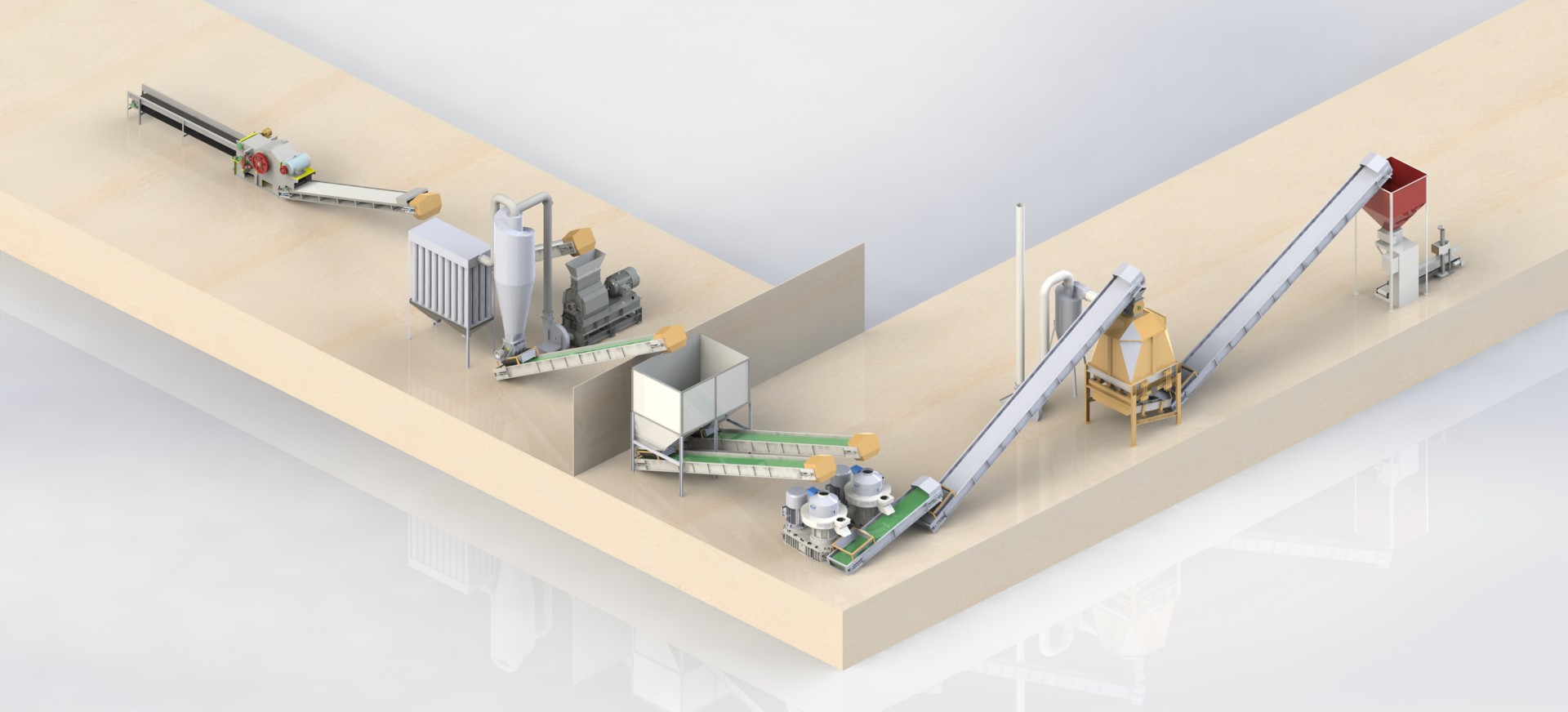

Wood pellet mill production line mainly includes 6 sections: Crushing section/Hammer section/Drying section/Pelletizing section/cooling section/packing section

Production Process:

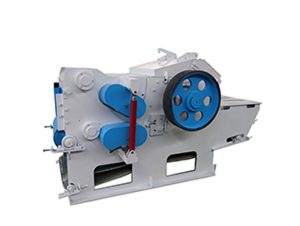

1.Crushing section: The wood chipper first crushes the waste wood into 3-5cm wood chips

2.Hammer section: Crush 3-5cm wood chips into 3-5mm sawdust

3.Drying section: Drying the moisture of the wood chips into 10-15% of moisture suitable for pelletizing

4.Pelletizing section: The pelleting machine will make sawdust with appropriate size and moisture into 6/8/10mm pellets

5.Cooling section: The temperature of the pellets just out of the pellet machine will be hot, need the cooler to cool the pellet. If you don’t use the cooler, you can choose to make a large silo for natural cooling

6.Packing section: Pack the cooled pellets, the weight of the package can be changed according to your needs

www.woodpelletmill.cn

www.woodpelletmill.cn