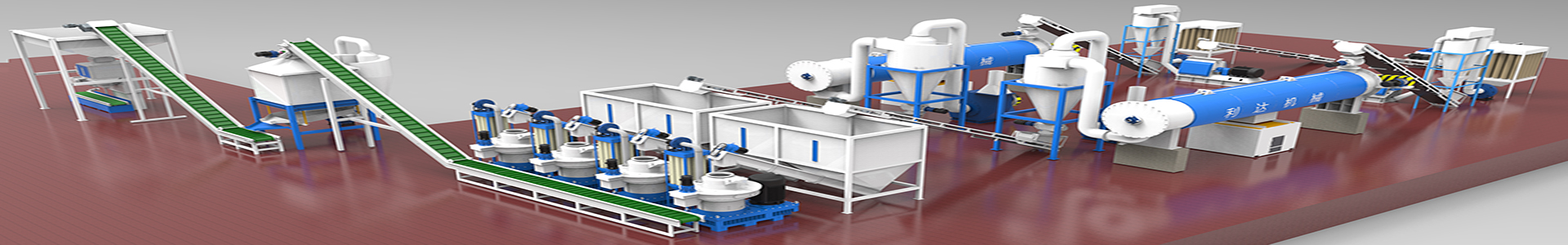

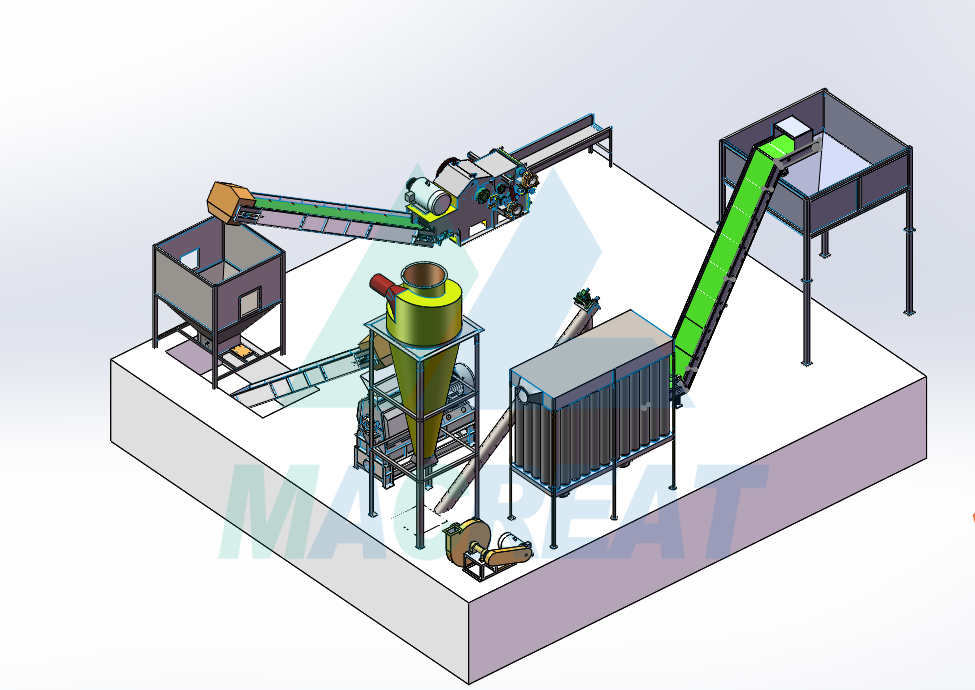

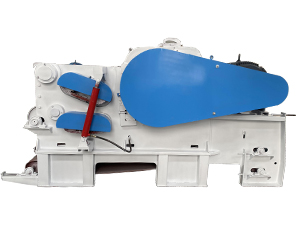

1. Crushing section: First size reduction, turning the long &crude logs into wood chips within 30-50mm (L*W). The capacity won’t be affected by the moisture content.

2. Pulverizing section: Secondary size reduction, when the capacity is not large, as well as the logs moisture less than 45%, the wood chips from previous section will be further pulverized and grinned into sawdust, within 5-8 mm. The capacity could be strictly affected by the moisture content.

3. Drying section: To produce pellets it is important to reduce the moisture into 10-15%, thus after reducing the size of all materials, they need to be dehydrated by a dryer. The capacity could be strictly affected by the moisture content.

4. Pelleting section: The full process is a complete physical change. By the spinning of the main shaft, it drives the rollers of the pellet mill to push the materials into the trumpet gaped holes of the pellet mill ring die, and the materials are firmly compressed into shape. There are no any chemical adheres are applied at all.

www.woodpelletmill.cn

www.woodpelletmill.cn