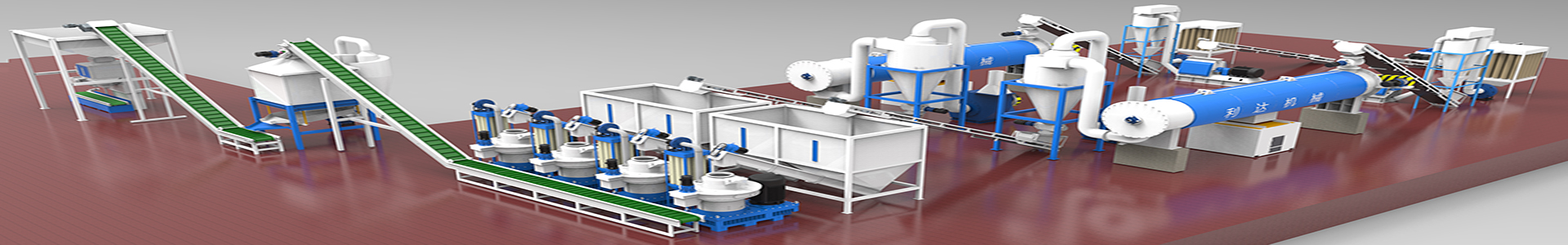

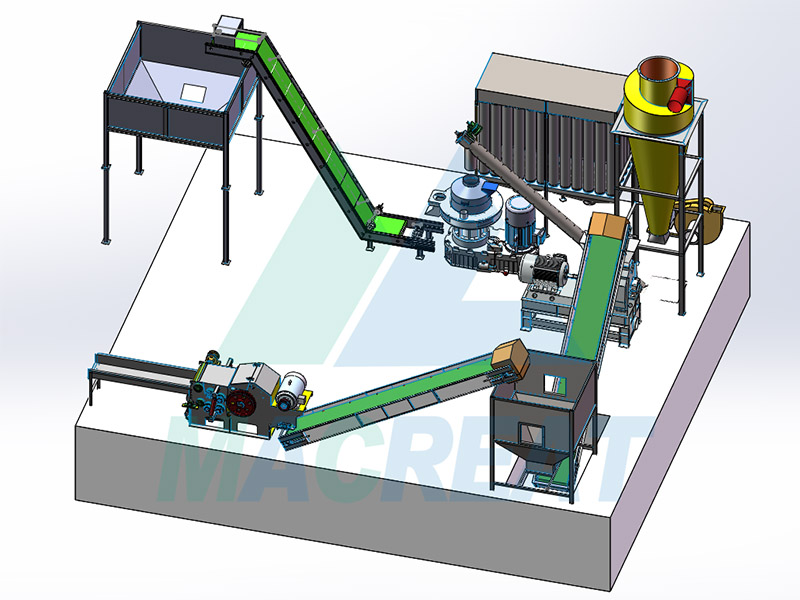

1. Crushing section: First size reduction, turning the huge chunks of the EFB chips into within 30-100mm (L*W). The capacity won’t be affected by the moisture content.

2. Pulverizing section: No matter what moisture condition the materials are, Macreat suggest that better apply twice-grinding for processing palm EFB. Palm fiber has extremely high toughness, it will become silky after the first pulverization, and can reach the standard only after the second pulverization.

3. Drying section: To produce pellets it is important to reduce the moisture into 10-15%, thus after reducing the size of all materials, they need to be dehydrated by a dryer. The capacity could be strictly affected by the moisture content.

4. Pelleting section: The full process is a complete physical change. By the spinning of the main shaft, it drives the rollers of the pellet mill to push the materials into the trumpet gaped holes of the pellet mill ring die, and the materials are firmly compressed into shape. There are no any chemical adheres are applied at all.

www.woodpelletmill.cn

www.woodpelletmill.cn