We can guarantee:

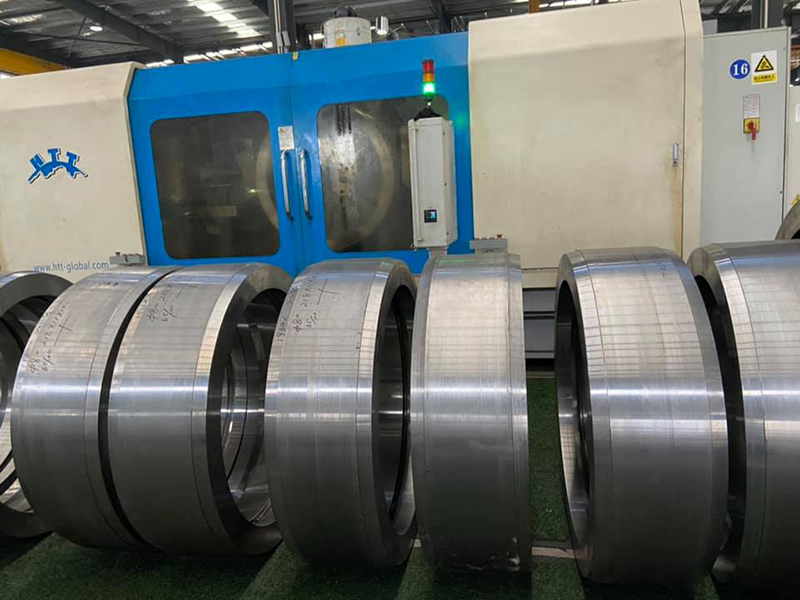

• High quality Alloy & Stainless Steels as raw material, processed with extremely precise manufacture;

• Perforation and mirror polishing of holes;

• Vacuum heat treatment, making the die much more durable and better pellet quality;

• Minimum die deformation after heat treatment;

• Test and control before delivery

• All dies are through hardened to 55-60HRC.

www.woodpelletmill.cn

www.woodpelletmill.cn