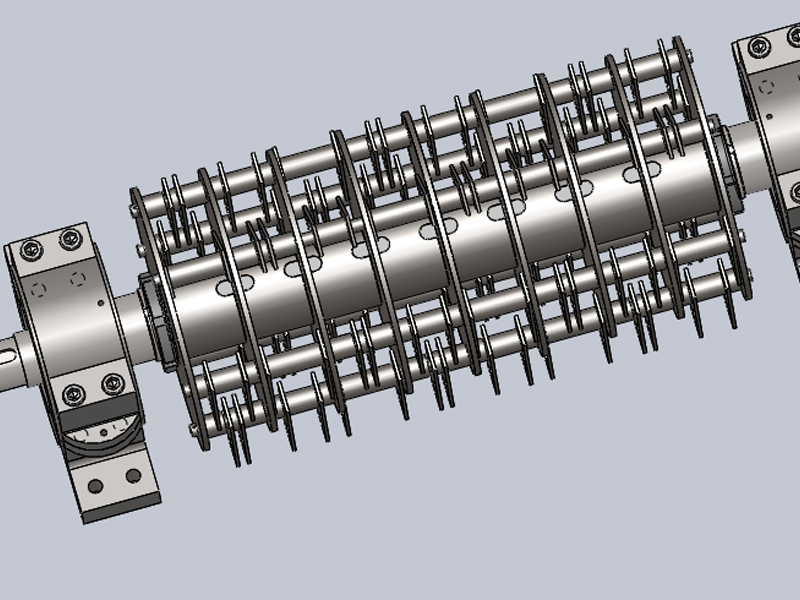

1.Hammer mill grinding machine will be passed by the dynamic balance testing, the error of hammers is within 0.2g, which can guarantee the machine runs stably.

2.The bearing seat is made of bearing steel, which is large and wide to ensure stable operation.

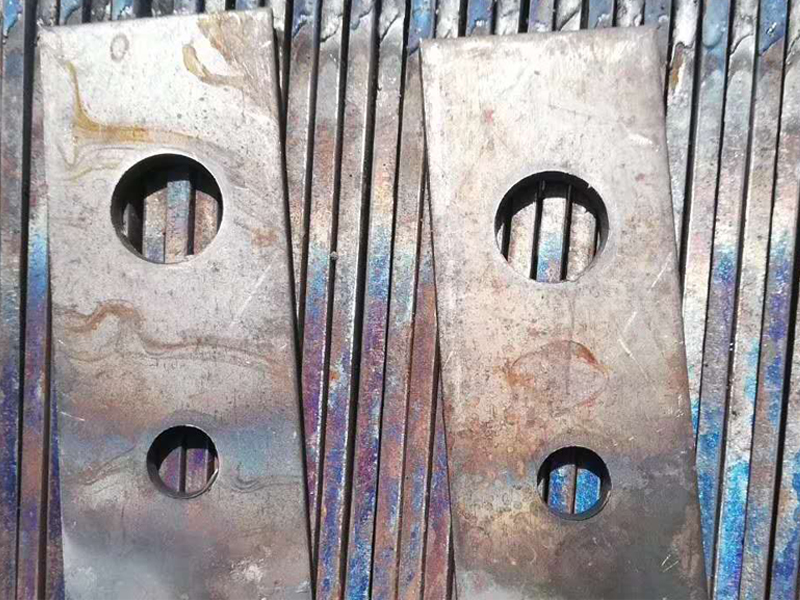

3.The raw material of hammers is tungsten carbide welding. The hammer is thick, and the crushing effect is better.

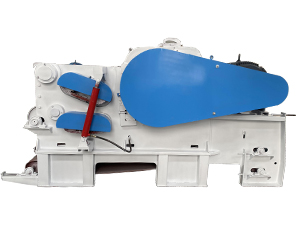

4.The feed inlet of hammer mill with anti-caulking baffle to prevent material collapse. And the machine is fed vertically, so the feeding is smoother.

www.woodpelletmill.cn

www.woodpelletmill.cn