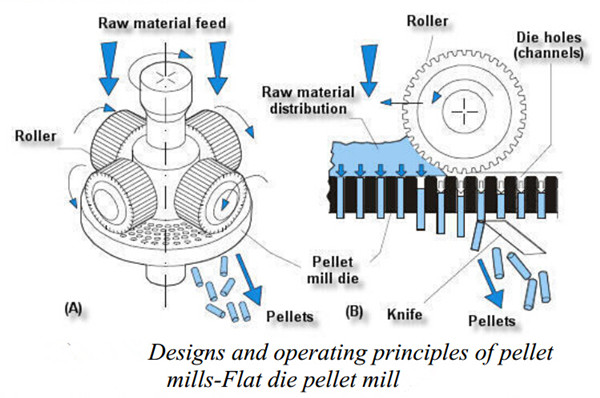

1.Flat die pellet mills are small in size and light in weight because of the compacted structure design.

2.Flat die pellet mils are easier to be cleaned and maintained and cheaper because of the design of portable rollers and die.

3.Flat die pellet mils are more convenient for you to monitor the process of pelletizing by watching the pelletizing chamber which make the experiment of indeterminate materials for raw materials expansion easier.

4.The disadvantages of pellet mills are they are not suitable for large scale pellet production. And also the gap between the roller and the die is tricky which should be adjustable according to the species of the raw materials especially the hardness of the raw materials.

www.woodpelletmill.cn

www.woodpelletmill.cn