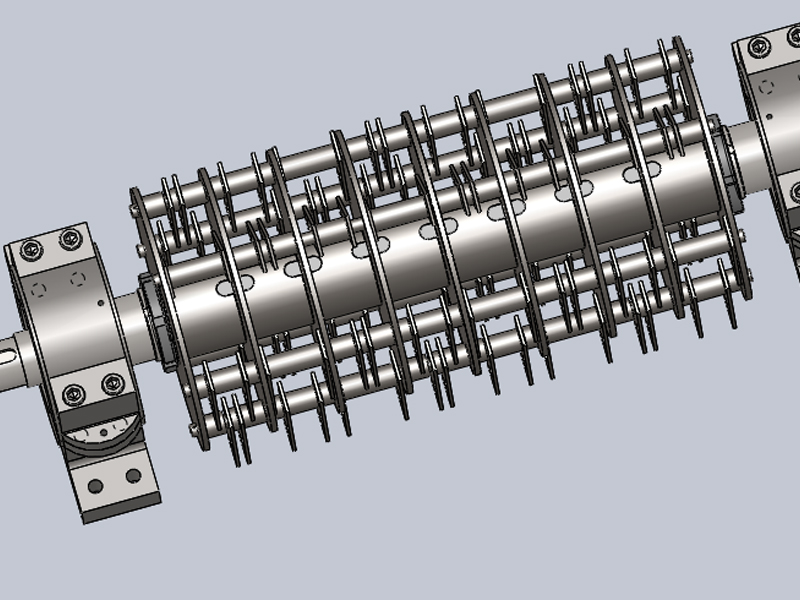

1.It contains two rotors and they rotate relative to each other, which leads to better performance compared with single shaft type.

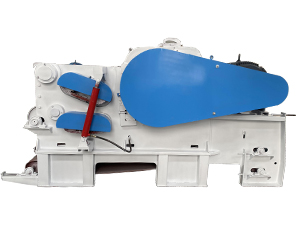

2.It adopts welded-steel plate construction, machine is embedded for seal.

3.Forged hammers has symmetric homogeneous permutation, small vibration without blind angle, large crushing friction area.

4.After balance calibration, rotors can work reversely.

5.Operating door has safety interlock to make sure it can not be opened when running.

www.woodpelletmill.cn

www.woodpelletmill.cn