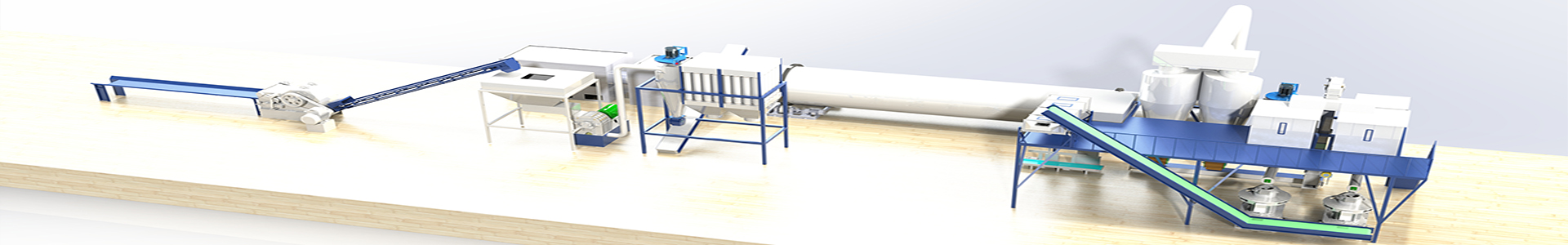

2-3 t/h wood pellet line in Wen zhou, Zhe Jiang Province in China.

(Click below pic will lead you to live video)

| Raw material | Sawdust and wood block. |

| The moisture of raw material | Less than 20%. |

| Model we use | Hammer mill GPX65*100 |

| Pellet machine LD720 | |

| 10m3 cooling bin and packing machine. |

| Recycled Material Granulation: Through treatment and processing of multiple waste boards, sawmill scraps, and demolition waste as raw materials, it is formed into high-density biomass pellet fuel, which perfectly turns waste into treasure and saving storage space. This creates huge economic and social benefits for customers. Raw Materials: mainly are sawmill scraps, recycled wood chips and demolition materials mixed with a certain proportion of door panels and waste panels Actual Output: 2000-2200 kg/h |

| Process introduction: Put all kinds of waste boards and waste wood into the Mingchuang 216 drum chipper with a unified grasping machine, and uniformly process wood chips that are 30-50mm in length and width, and the thickness does not exceed 14mm; The pre-processed wood chips are fed into the Mingchuang GXP65*100 high-efficiency hammer mill through a conveyor belt, and they are crushed into 5-8mm sawdust and sawdust. Because the recycled wood selected by the customer is ideally 12-15% moisture, the sawdust obtained through crushing and fine pulverization is directly fed into the Mingchuang special centrifugal high-efficiency pelletizer LD720 through the screw conveyor, and 8mm particles are directly pressed, and use customer-made 10 cubic meters of heat-dissipating buffer warehouse to cool down and use a comprehensive packaging scale to pack and sell the pellets. This production line has a reasonable layout, is easy for customers to operate and maintain, and meets customers’ requirements for dust-free production. So far, it has continuously created a lot of revenue and profits for customers! |

www.woodpelletmill.cn

www.woodpelletmill.cn