We also have a triple-pass dryer project exported to South Africa. The triple-pass dryer is safer than traditional vacuum dryers. Compared with ordinary rotary dryers, the output and energy saving have been greatly improved. Customers are very interested in this.

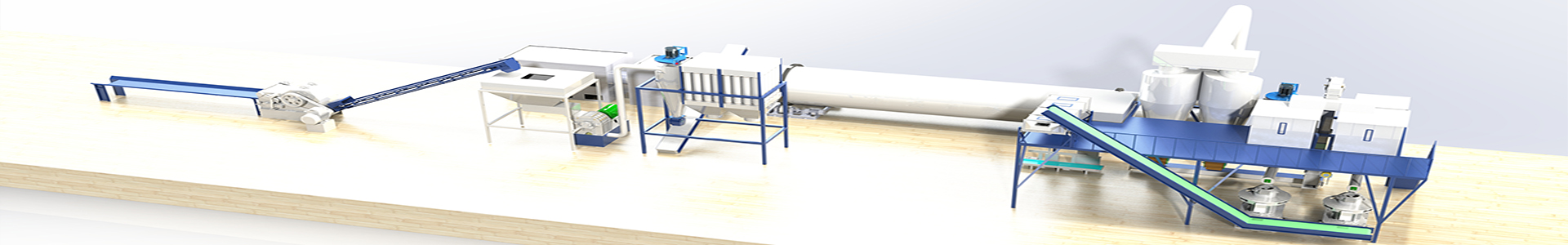

The Triple-pass sawdust dryer machine is composed of three layers of inner, middle and outer cylinders.

The wet material enters from the inner cylinder. In the interior of the dryer, wet material goes through from the inner cylinder to the middle cylinder and then the outer cylinders.

The dried material is collected with a separator from the outer cylinder’s tail.

Hot air enters from the inner cylinder and exits from the tail of the outer cylinder.

The cylinder is equipped with a forward board so that the material is continuously picked up and sprinkled during the rotation of the cylinder.

That makes material fully in contact with the hot air flow, improves the drying efficiency and achieves the drying effect of the material.

Advantages

1. The required investment of the equipment is 1/6 of the imported products other countries;

2. The self-heating thermal efficiency of the dryer body is as high as 70% (the thermal efficiency of the traditional single drum dryer is only 35%), and the heat efficiency is increased by more than 50%;

3. Compared with the single drum dryer, it will reduce the land occupation by about 50%; the civil construction investment will be reduced by about 50%; the electricity consumption will be reduced by 60%;

4, Combination of Multi-directional lifting, which can regulate of drying time effectively and get good drying effect;

5, According to user requirements, the dryer can easily regulate the final moisture as customer desired;

6, Use frequency control speed to control material flow;

7, The outlet temperature is low, dust collecting equipment can have longer working time, the dryer can be continuous production for the next process;

www.woodpelletmill.cn

www.woodpelletmill.cn