A domestic customer bought our production line with a production capacity of 1 ton to process the discarded fruit trees in the orchard. The pellets effect is very good.

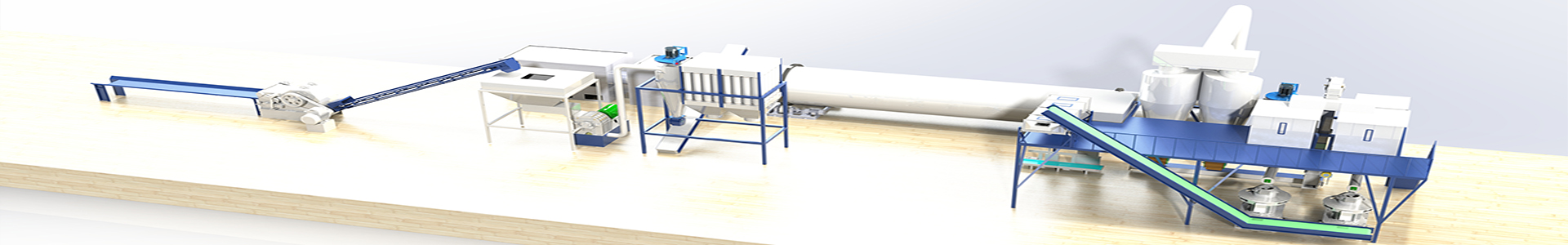

Our whole production line includes Wood Chipper, Hammer Mill, Dryer, Pellet Mill, Cooler and Packaging Machine.

The drum wood chipper is professional in cutting wood log, branches, veneer, batten, bamboo, bracket, various bale of straw (rice straw, corn straw, cotton stalk) and other wood materials into 3-5cm wood chips. Sharpen blade material is H12. It is widely used in the flakeboard plant, medium- and high-density fibreboard plant, furniture factory, biomass power plants, wood plants and the raw material preparing process of the manufacturers. This machine have the characteristics of high capacity, good quality and also easy to operate and maintain .

GXP series hammer mill is a type of wood crusher that can produce sawdust. The raw material of hammer mill for sale are wood chips, wood shavings, agricultural straw, stalk, rice husk, peanut shell, corn cob, wood branches etc.

The three-way drum dryer is composed of three layers of inner, middle and outer cylinders. The wet material enters into the inner layer. Inside the dryer, the wet material goes from the inner cylinder to the middle cylinder and then to the outer cylinder. A separator from the tail of the outer cylinder is used to collect the dried material. Hot air enters from the inner cylinder and exits from the tail of the outer cylinder. The cylinder is equipped with a front plate to continuously pick up and spray material during the rotation of the cylinder. This makes the material completely contact with the hot air flow, which improves the drying efficiency and achieves the drying effect of the material.

The new vertical ring die pellet machine is a new type of biomass fuel production machinery, which can be used to process forestry and agricultural wastes such as eucalyptus, pine, birch, poplar, fruit and agricultural straw, bamboo and other agricultural wastes. Compared with the old machine, it absorbs the essence of the horizontal ring die and flat die pellet machine, solves the problem of insufficient pressure and mold cracks in the horizontal ring die pellet machine, and overcomes the small capacity and high failure rate of the flat die pellet machine problem.

Raw material requirements for centrifugal high-efficiency pellet machine:

Raw material size: ≤5mm

Water content of raw materials: 10-15%

Particle selection:

Length: 2cm-40cm

Diameter: 6/8/10mm

Cooler is a machine which adopting counter-current cooling principle to cool down the pellets. Cooling air moved reversely with high temperature and high humidity material, so that the material from top to bottom can gradually get cooling.

Packing machine is used for packing the pellets in requirement capacity to bags and seals bags automatically.

It is mainly used for the packing of granular material with good liquidity. It has fast speed, highly precision, automatic weighing, conveying and sealing bags. According to customer’s need, the machine can be set per pack capacity. Control cabinet adopts sealed form, suitable for harsh dust environment. Packing machine can be designed to be fixed or mobile body.

www.woodpelletmill.cn

www.woodpelletmill.cn