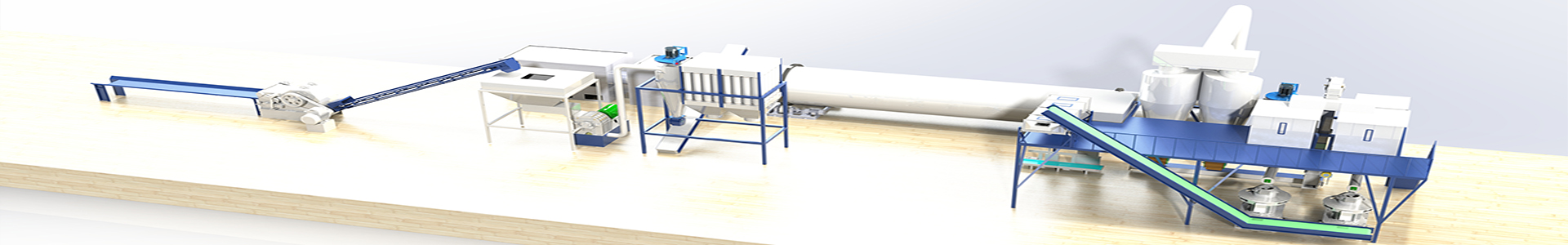

3-4 t/h Wood scraps pellets production line in Indonesia

(Scan the QR code or Click below pic will lead you to live video)

Raw material Wood scraps

The moisture of raw material 50%

Output requirements 3-4t/h

Model we use Drum wood chipper BX218

Efficiency hammer mill GXP65*100

Dryer

LD700 1.5-2t/h pellet mill

Cooler SKLN2.5

Small packing machine DCS-A50

Process introduction:

1.Rough crushing: use wood chipper machine breaks white pine logs into 3-8cm wood chips

2.Fine crushing: grinding the 3-8cm wood chips into 3-5mm saw dust

3.Drying: The dryer reduces the moisture content of the crushed wet wood dust from 50% to 10-15%

4.Pelletizing: the pellet mill machine will make the dried wood chips into pellets through pure physical extrusion

5.Cooling: The cooler cools the finished pellets to natural temperature

6.Packaging: the packing machine packs the cooled pellets

www.woodpelletmill.cn

www.woodpelletmill.cn