1-1.5T/H Wood Pellet Making Line Case

Project Profile:

Purpose: Disposal plywood waste for their own factory usePlant Location: China

Purpose: Disposal plywood waste for their own factory use

Raw Material: Plywood Waste

Estimated Investment Budget: $80000 EXW Factory

| Plant Capacity and Operating Hours | ||||||

| Plant Size |

24*50*10m(W*L*H) |

|||||

| Pellet size 1 | Pellet size 2 | Others | ||||

| Oper. days yearly | 300 | days | days | days | ||

| Oper. hrs daily |

12 |

hours | hours | hours | ||

| Capacity ton/h | 1 | tons/h | tons/h | tons/h | ||

| Raw Material Descriptions | |||||

| Wood Species | Material Shape | Particle Size (L*W*T) mm | Moisture | % of Supplied | |

| 1 | Poplar | Strip | 1100*500*200 | ≤10% | 60% |

| 2 | Poplar | Powder | ≤10% | 40% | |

| Electricity | |||

| Frequency: | 50Hz ±0.2% | 60Hz ±0.2% | Others |

| Main Supply Voltage | 380 V | 415 V | Others |

| Max Available Power at Site (kVA) | 600kVA | ||

|

Pellet Quality |

||||||

|

Pellet size 1 |

Pellet size 2 |

Pellet size 3 |

||||

|

Pellet diameter mm |

8 |

mm |

mm |

mm | ||

|

Fines % |

≤2.5 |

% |

% | % | ||

|

Additives % |

≤0.05 |

% |

% | % | ||

Pellet Making Process

- Chipping Process

The plywood strip can be crushed by wood chipper machine into chips and its size is 2-5cm.

- Crushing Process

The chips can be crushed by Hammer Mill into sawdust and its size is 3-6mm.

- Pellet Making Process

The sawdust can be squeezed by Pellet Mill into pellet and its diameter and length can be adjusted.

- Cooling Process

The pellet can be cooled down naturally by stock bin. For quick process, cooler can be optional.

- Packing Process

The pellet is packed and stock for use.

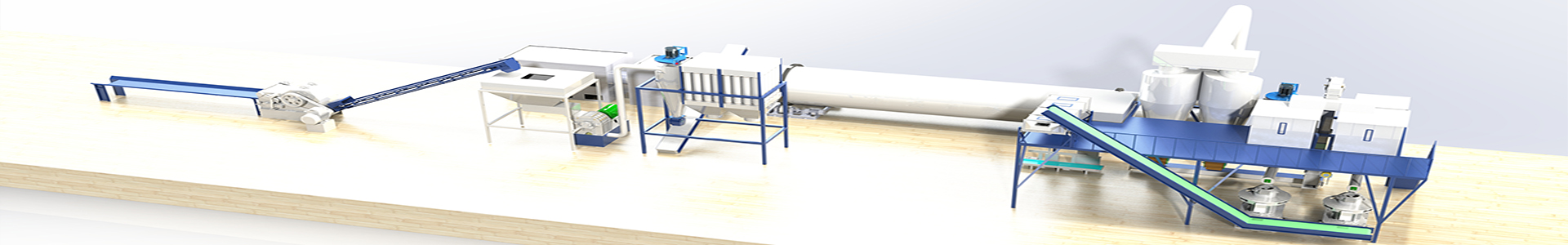

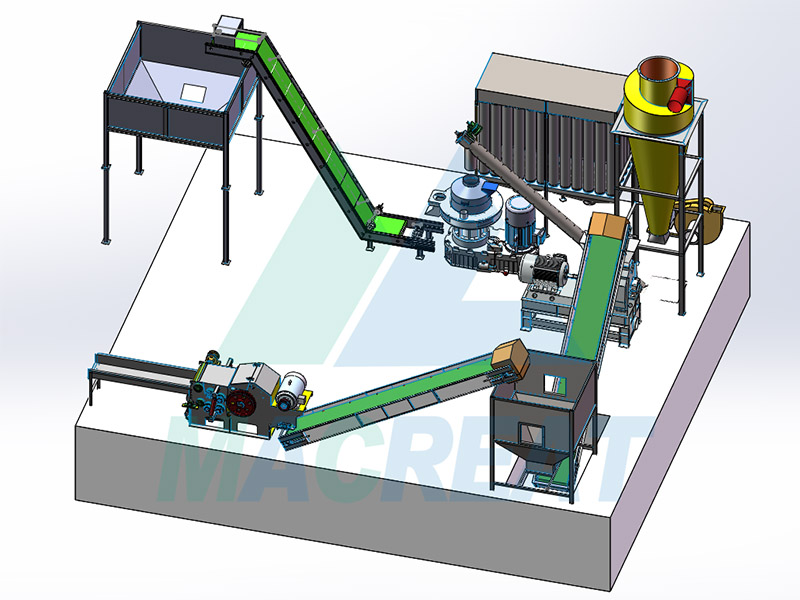

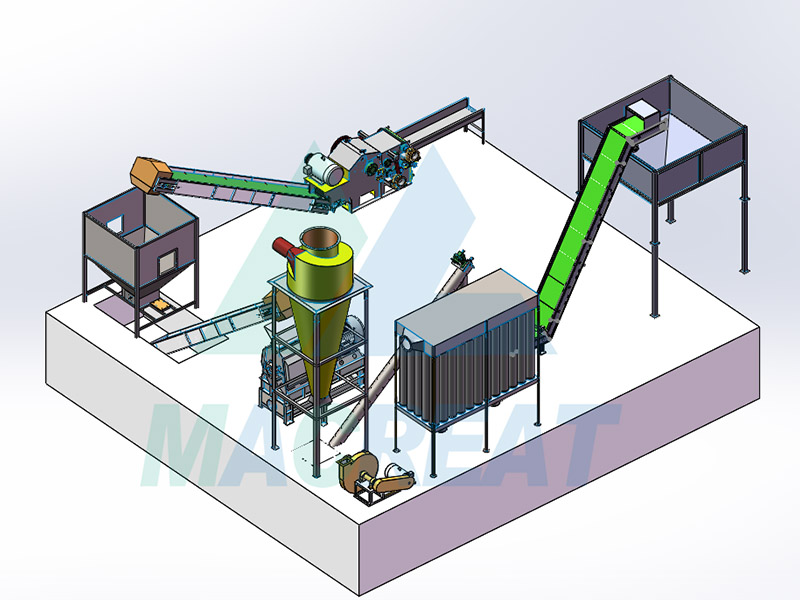

Diagram Display

Site Photos

www.woodpelletmill.cn

www.woodpelletmill.cn