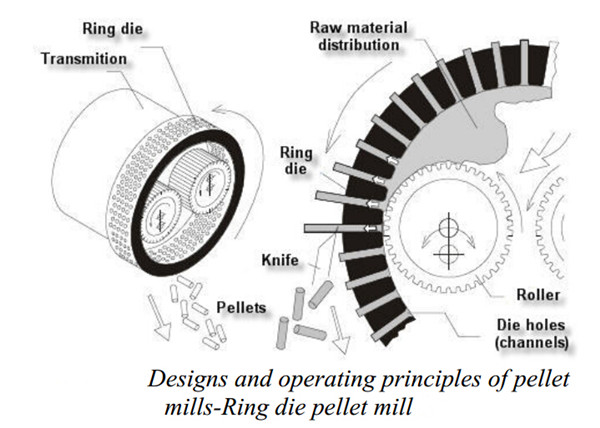

1. The material is fed vertically, and the material can be directly fed into the granulating chamber.

2. Due to centrifugal force, the material is evenly distributed around the granulation chamber.

3. Double-layer molds can reduce costs. High efficiency and energy saving, after a period of time, the other side can be changed to ensure high-quality particles. The mold is stationary and the rollers rotate; due to centrifugal force, the material is evenly distributed around the granulation chamber.

4. The ring die and vertical structure are conducive to cooling the granulation chamber.

5. The combination of squeezing force and centrifugal force can ensure the molding degree and high density of the particles.

6. The automatic intermittent lubrication system extends the service life of machine parts, and the machine can run 24 hours a day.

www.woodpelletmill.cn

www.woodpelletmill.cn